Die JAHN GmbH kann auf mehr als 30 Jahre Erfahrung mit Aluminiumerzeugnissen zurückblicken. Hinter den Innovationen und Neuerungen der Vergangenheit – aber auch denen der Gegenwart und Zukunft – stehen modernste Fertigungstechnologien und Verfahrensweisen.

Mit dem Anspruch auf zeitgerechte Konzepte beschäftigen wir mehr als 30 Ingenieure und Techniker, welche täglich zu verschiedenen verfahrenstechnischen Themenbereichen entwickeln und forschen. Auf diese Weise können wir nachhaltig den professionellen Rahmen bieten, den unsere Kunden von uns erwarten.

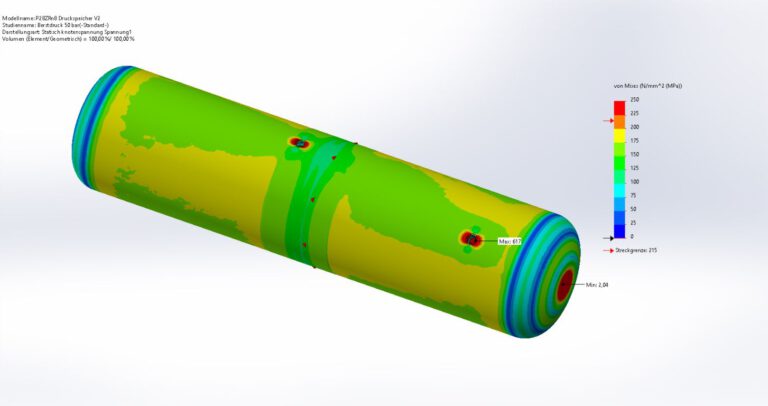

3D-Simulation eines asymmetrischen Pressteils durch Fliesspressverfahren

2D-Simulation eines rotationssymmetrischen Pressteils durch Fliesspressverfahren

Als Ergebnis unserer Arbeit konnte eine Vielzahl von innovativen Lösungen als Patent angemeldet werden. Hierzu zählen u. a. die Anwendungsbereiche Kühlmedien, Speichervorrichtungen und Umverpackungen.

Durch unseren Vorsprung durch gesichertes und geschütztes Wissen können nicht nur wir, sondern auch unsere Kunden direkt profitieren.

Bei unseren Herstellungsmethoden legen wir Wert auf bestmögliche Qualität bei jedem einzelnen Erzeugnis. Aus diesem Grund garantieren wir unseren Kunden zertifizierte Standards, auf die sie sich im Rahmen einer Partnerschaft verlassen können.

Wir verstehen die Zertifizierungen unserer Prozesse als fortlaufenden Prozess. Somit streben wir langfristig danach, weitere Zusicherungen unserer garantierten Leistungsfähigkeit zu erwerben. Nur so können wir den nachhaltigen Erfolg unserer Kunden sicherstellen.

Umform- und Zerspanungstechnik

Im Grund 1-9

D – 99897 Tambach-Dietharz

Tel: +49 36252/ 464 – 0

E-Mail: info@jahngmbh.de

Für Besuche steht unsere Hauptverwaltung (Im Grund 1) mit mehreren Konferenzräumen zur Verfügung.

Kontaktieren Sie uns für einen gemeinsamen Termin über unser Kontaktformular.